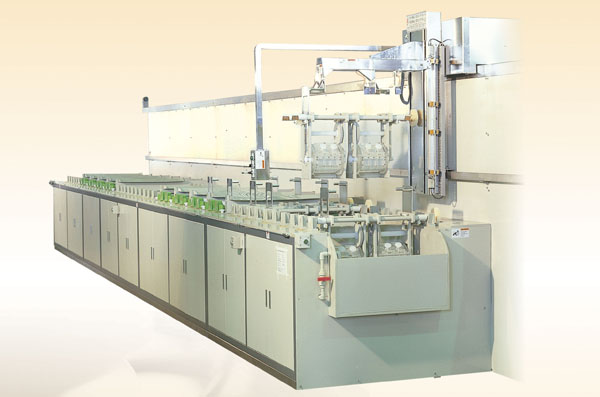

Single Arm Type Barrel Plating Equipment

Product Description

- Both the Single Arm Type Barrel Plating Equipment and the Tilted Bowl Type Plating Equipment are suitable for very small size, delicate, and light weight products that require plating film with high levels of precision and uniformity, such as MLCC, capacitors, resistors, or connectors.

- Single Arm Type Barrel Plating Equipment requires only small area of work space and provides ease for work along bath tanks.

|

|

|